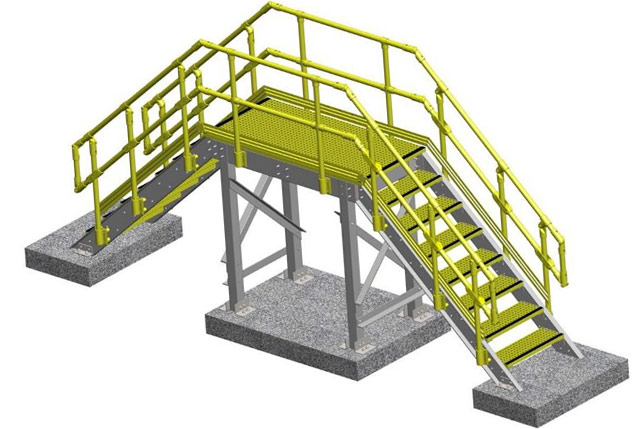

FRP Access / Non Conductive Stair Crossover Platforms

Pre-Engineered crossover platforms by Staircare Access Systems division were developed as a cost-effective, standard solution to meet customer’s special requirements that would normally necessitate custom solution.

Staircare Handrail Fiberglass Reinforced Plastic (FRP) Handrail Systems are safe, corrosion resistant, virtually maintenance-free, and easy to install.

Our standard industrial handrail is a 2-rail system with kick plate fabricated from high strength pultruded structural shapes with UV inhibitors manufactured into the resin and synthetic surfacing veils that allow a resin-rich surface.

Standard systems are produced in safety yellow, with other colours available upon request.

Handrails are available prefabricated and factory assembled or can be shipped in components for easy on-site field fabrication. A factory applied UV coating is recommended when handrails will be utilized outdoors.

Why use FRP Stair Crossover Platforms?

Corrosion Resistant

Our FRP products are known for their ability to provide corrosion resistance in the harshest environments and chemical exposure. Our products are built to last and do not rust or rot.

Slip Resistant

Our fibre-grating surfaces and stairs provide excellent slip resistance for most environments. This improves worker safety and reduces slips and falls.

Easy Installation

Our FRP stair crossovers are light weight and easy to install. Our FRP products eliminate the need for heavy lifting equipment or hot work permits for significant added convenience and cost savings.

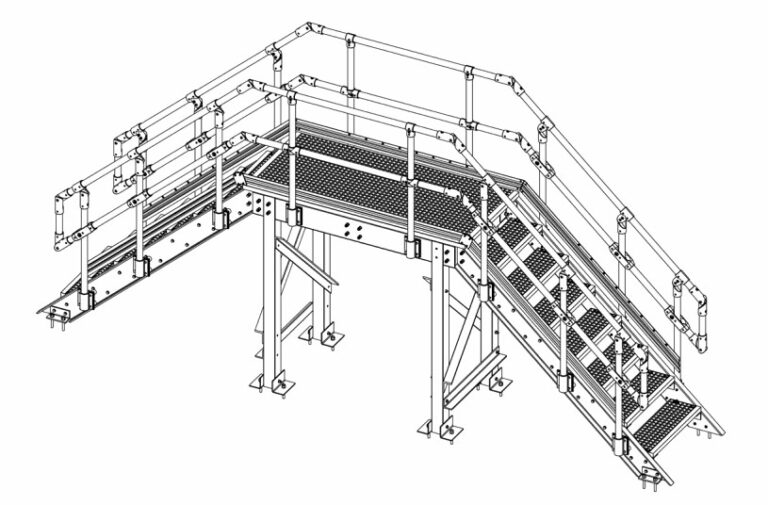

Assembly Instructions

Step 1: Support Legs

Cutting FRP Square Hollow Sections (SHS) to the desired size and join them with Equal Leg Angle (ELA), Stair tread assemblies inside of C-Channels on Platform Assembly and line up the holes.

We use slide brackets to support the handrail and use different FRP fixings for assembling the handrail using a round tube (anti-crush) to avoid crushing SHS. We use M12 hex head bolts for assembly (M12 bolt, 2 each flat washers, and M12 nut).

Prior to use, the support legs must be anchored to the supporting surface to prevent tipping, chemical anchor holes are M16 and located at the bottom of each leg.

The illustration shown in these instructions may vary from the crossover you are assembling (click to expand).

Step 2: Stair Assembly with Handrails

Staircare use C-Channels for structure stair, we use slide brackets to support the handrail and different FRP fixings for assembling.

Staircare’s pre-engineered crossovers are constructed utilizing fiberglass reinforced plastic (FRP) structural profiles, FRP grating and stair treads, typically with an optional anti-slip surface which provides superior slip resistance in most environments, including oily or wet conditions. Staircare structural components and round handrails create a durable and safe crossover.

The standard colours for the system are Light Grey for the structural frame, Industrial Yellow or Green for the grating and treads, and Safety Yellow for the handrails.

Step 3: Platform Assembly

Cutting FRP Square Hollow Sections (SHS) to the desired size and join them with Equal Leg Angle (ELA), Stair tread assemblies inside of C-Channels on Platform Assembly and line up the holes.

We use slide brackets to support the handrail and use different FRP fixings for assembling the handrail using a round tube (anti-crush) to avoid crushing SHS. We use M12 hex head bolts for assembly (M12 bolt, 2 each flat washers, and M12 nut).

Prior to use, the support legs must be anchored to the supporting surface to prevent tipping, chemical anchor holes are M16 and located at the bottom of each leg.

The illustration shown in these instructions may vary from the crossover you are assembling (click to expand).

For more information see below product information sheets or contact our friendly and experienced team who will be happy to assist with any queries and a quote.